|

About US

- Temasek Polytechnic, School of Business

- Diploma in Logistics & Operation Management - Year 2's Students - Doing a project on the topic 'Storage Systems' Topics Discuss

Facilitator's Question

Storage Systems Factors contributing to a well-designed storage sy... What factors determine the choice of storage systems? Overview of other Palletised Storage Video on Palletised Storage Double-deep Pallet Racking Drive In Drive Through Shelving Overview of Small Item Storage Voice out

|

Facilitator's Question

Sunday, January 13, 2008 @ 1:07 AM

Under what circumstance the powered mobile rack (as shown in your Blog) becomes a preferred choice instead of other storage systems? Explain. Powered Mobile Rack is a preferred choice when the warehouse space is limited and space utilisation is a crucial factor to the warehouse. This is because, this type of storage system has good space utilisation as space for only one aisle is needed for fork truck access. Powered Mobile Rack gives a very dense storage, and is suitable for the typical large number of product lines of a product range, where individual SKUs have low inventory and low throughput. It is especially useful in cold-store applications where space costs are especially high, and where temperature variations are reduced by minimizing the air space in the storage area. Space utilization is as high as 90%. The concept of Mobile Shelving eliminates all those wasted aisles - reducing them to a manageable number, while still providing for the multiple access required by your application. Mobile racking is based on a block storage layout. Each bay is mounted on rails, which allows it to be moved into position when required, offering superior space saving capabilities with 100% accessibility. Powered Mobile racking maximizes space utilization, enabling up to 80% of the floor area to be occupied for storage, compared with 30% for conventional wide-aisle pallet racking. The versatility and efficiency of this system makes it particularly suitable for use in cold stores, bulky multi-product applications, palletize consumer goods and food products. It allows the movement of a single aisle within a solid block of racking which exposes the required rack face, this then allows easy access to individual pallets and facilitates efficient stock control. This will thus leads to higher productivity and efficiency. Furthermore, each installation incorporates photo-electric trip mechanisms and fail-safe systems which will ensure maximum safety for operatives thus providing the ease of using it. Powered Mobile Storage system offer the industry's widest selection of safety features. Space saver systems are custom-designed to meet individual capacity needs and can move up to 80,000 pounds (36,200 KG) and more with just the push of a button. Synchronous carriage design and welded steel construction guarantee easy movement and long system life. Powered Mobile Storage provides protection for the system's users, the materials and the system itself thus it is more superior as compared to the other storage systems. Unlike standard pallet racking, which requires a relatively large proportion of floor space to be used for aisles between the rows of pallets, the block arrangement is extremely space efficient. Mobile racking compliments the drive in and narrow aisle space saving racking systems for specialist applications. Space Efficient Mobile racking places rows of pallets adjacent to each other in a block, with no aisles between. Less floor space required for aisles means more floor space available for storage. The bays of mobile racking are located on guide rails set into the floor and are electrically operated to bring each one forward as required for loading or unloading by fork lift truck. In this way, all the advantages of “block” racking are achieved whilst maintaining full access to each individual pallet. Each “block” requires only one aisle and conventional fork lift trucks can be used. In Control Access to each bay is achieved using either a pre-programmed remote control or individually at the push of a button. Each block can be locked in position for additional security for valuable goods. This gives warehouse managers complete control over their stock and throughput. Storage Systems

Saturday, January 5, 2008 @ 10:47 PM

What is a Storage System? Storage system can be separated into two important functions: inventory holding (storage) and material handling. These functions can be seen by tracing product flow through a typical distribution warehouse. Material handling refers to those activities of loading and unloading, moving the product to and from various locations within the warehouse, and order picking. Storage is simply the accumulation of inventory for a period of time. Different locations in the warehouse and different lengths of time are chosen, depending on the purpose for storage. Within the warehouse, these move-store activities are repetitive and are analogous to the move-store activities occurring between various levels of the distribution channel. Thus, in many ways, the storage system is a micro level distribution system. Specific identification of the major activities promotes understanding of the system as a whole and helps to provide a basis for generating design alternatives. Rack A rack is the generic name given to any kind of storage fixture which cannot be classified as shelving or binning. Racks for the accommodation of palletized stores, tubes, bars, sheets, plates, tires, cables, and drums are the commonest types encountered in storehouses, but there are many racks designed for special purposes, e.g. shovels, ‘V’ belts, chains and a wide variety of heavy stores. Storage Systems are divided into 3 categories and each category consists of different types of storage system. Here are the overview of the various types of storage systems. Palletised Storage

Small Item Storage

Odd Size Storage

We will be focusing more on Double Deep Pallet Racking, Drive-in Drive-through and Shelving in our blog. Factors contributing to a well-designed storage system

Friday, January 4, 2008 @ 10:47 PM

A well-designed storage system should have the following seven criteria:

What factors determine the choice of storage systems?

Thursday, January 3, 2008 @ 10:52 PM

In most projects, the storage and throughput requirements are defined based on the proposed process and projected volumes and then the goal is to optimize productivity, storage density, and capital cost. The following factors are considered when deciding the appropriate storage medium for the warehouse.

Overview of other Palletised Storage

@ 10:47 PM

Adjustable Pallet Racking is designed with single rows or back-to-back rows and multiple levels. The depth and width are defined by the unit load footprint, usually a pallet, and height is adjustable to conform to varying unit load heights. With an aisle between each row, this arrangement provides excellent pallet load accessibility but has a low storage density. The amount of aisles and single-deep density results in decreased warehouse space utilization.  __________________________________________________________________________________________________________ Block stacking is where multiple unit loads are stored in designated floor location that is multiple levels high. __________________________________________________________________________________ Most storage equipment simply provides a static location for the housing and protection of stock, but in some cases it is found to be desirable to provide for the movement of materials held within the fixtures. Equipment which enables this movement goes under the generic heading of ‘live storage equipment’, and is particularly useful where stock rotation is of great importance.

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

The storage equipments moved by simply sliding the equipment along the tracks, by turning a crank located at the end of each storage row, or by invoking electric motors that provide the motive power.  The idea is that instead of having fixed bins with gangways between each fixture, the bins are mounted on rails or tracks. The bins are thus able to be placed close to each other, and the floor space which would otherwise be needed for gangways can be used for storage. When access to a particular bin is needed the fixtures are parted at the appropriate point by sliding them along the tracks. In the lighter type of installation simply pushing the fixtures is all that is necessary, is though most arrangements of this type have some kind of rack and pinion arrangement to make movement easier. ___________________________________________________________________________________________________________________________

Narrow aisle pallet racking allows more pallets to be stored than adjustable pallet racking. This is because the aisles are narrower, and the trucks can lift higher. Narrow aisle racking is served by specially designed trucks which do no need to turn through 90 degrees but run on a fixed path between the racks and pick up and set down on either side as required. As a result, the aisle is only marginally wider than the handling equipment which operates within the confines of the system. Goods are taken to and from the system by general purpose handling equipment which uses a pick and deposit station located at the ends of the narrow aisle. A High Rack Narrow Aisle can be as high as 20 meters tall.

The High Bay rack can be as high as 30 - 35 metres tall, in which the pallet movements are all depends on the stacker cranes, giving free access to all pallet locations. The racking structure may be used to support the walls and the roof of the building. Advantges: Disadvantages:

Video on Palletised Storage

@ 8:47 AM

Powered Mobile StorageDouble-deep Pallet Racking

Tuesday, January 1, 2008 @ 12:02 AM

A double-deep rack is basically a selective pallet rack that is 2 pallet positions deep. This rack is loaded and unloaded from the front, requiring stocking and picking activities in the same aisle.

Disadvantages: http://www.eseprojects.co.uk/palletstor-racking.asp#double-deep Drive In Drive Through

Monday, December 31, 2007 @ 12:04 AM

Drive In Rack A drive in rack gives a tunnel effect where the lift truck drives in through the storage rack. The lift truck operator drives into the rack and places the unit load in the innermost position, filling all positions until the rack is full. Since only the outermost loads are easily accessible for picking, last in, first out inventory rotation results. Primarily, this type of storage mode is used in distribution centre for medium to fast moving items that have nonstackable products and where FIFO, lot control, and expiration date are not required. For instance, if all that is being stored is one model or one lot number of microwaves and selectivity is not needed, then this may be a candidate for a drive in rack. The grocery industry or manufacturing storage and distribution is a good example where this type rack is utilized, especially in freezer storage for which maximum space utilization is needed. In the industry, push back racks and pallet flow racks are being used as alternative to drive in and drive through racks. Advantages:  - This storage method limits wasted aisle space and greatly improves the use of the storage space. - It is ideally suited to operations that maintain a large quantity of a relatively low number of SKUs. Disadvantages: - The reduction of lift truck travel speed needed for safe navigation within the confines of the rack construction. - The honeycombing losses because no more than one SKU should be housed in a lane. As a result, drive-in rack is best used for slow to medium velocity SKUs with 20 or more pallets on-hand. - Results in LIFO inventory rotation - Limits selectivity because loads must be removed vertically on each level before the next layer is accessible. As was the case with block stacking, loads should be retrieved with a LIFO discipline and with a retrieval discipline to free up each lane as quickly as possible. For the drive-in-rack, the number of unit loads deep per storage lane is varied to place building columns within the flue space of the back-to-back drive-in rack rows. The drive-in rack storage lanes are best designed between building columns. This feature means that the building columns are not in the drive-in rack storage positions or lanes. In all drive-in rack down-aisle designs, structural members require fire sprinklers and lift truck mast and overhead guard clearances. Most drive-in racks are designed with the fork-open  ing side of the pallet board facing the aisle. This arrangement has the maximum number of faces per aisle and provides excellent unit-load stability in the rack position. If possible, in a carton-handling (pick) operation, the rack has the 48-in (stringer) dimension or side of the pallet board facing the aisle. ing side of the pallet board facing the aisle. This arrangement has the maximum number of faces per aisle and provides excellent unit-load stability in the rack position. If possible, in a carton-handling (pick) operation, the rack has the 48-in (stringer) dimension or side of the pallet board facing the aisle.To make deposits and withdrawals in a drive-in rack storage concept, a lift truck enters the floor-level storage lane from aisle A, deposits or withdraws a unit load, and backs out the storage lane into the same aisle A. because of this operational characteristic, a drive-in rack can handle a medium volume and has a LIFO product rotation. Drive Through Rack  Drive-Through Racks allow a lift truck to enter the rack from either side to pick up or pull out pallets. Loads are supported by rails attached to upright frames, and lift trucks are driven between uprights to reach pallets. This is done because pallets can slide backwards on a continuous rail. It's open at both ends, allowing first-in, first-out storage. Drive-Through Racks offer the ability to store a large amount of similar loads in a smaller area. Selectivity is sacrificed, but storage density is enhanced since many pallets are stored and are available through a single pallet position. With no back bracing, drive-through rack is designed as a stand-alone rack row with a lift truck aisle on both sides. This means that it is not designed with back-to-back rows. This arrangement handles a medium volume, and the product rotation is LIFO or FIFO. With LIFO product rotation, the lift truck enters the storage lane from aisle A, deposits or retrieves the unit load, and backs out of the storage lane into aisle A. With FIFO product rotation, the lift truck enters the storage lane into aisle A, deposits the unit load in the unit-load position, and backs out (from the storage lane) into aisle A without a unit load from the storage lane. An alternative procedure in FIFO product rotation is to exit from the storage lane by driving without a unit load through the storage lane from aisle B, retrieves the unit load, and backs out of the storage lane into aisle B. Drive-through rack has medium storage density and poor unit-load accessibility. The dimension of the pallet load position has the same characteristics as that of drive-in racks. Shelving

Sunday, December 30, 2007 @ 12:06 AM

Bin shelving systems  Shelving is usually made from mild steel, in standard component sizes, to various heights, vertical shelf spacing and shelf depth which cater to different company’s exact needs. There is limited range of standard widths for the modules. Shelving can be as ‘short span’, usually 1 meter wide, and ‘long span’, 3 meters or more in width. Shelving is comparatively inexpensive, gives random access to stock, is modular, interchangeable and is easily moved. Separation of small quantities can restrict access. For instance, the hand access between vertical shelves partitions spaced 50 mm apart is limited. Bin shelving systems are the oldest and still the most popular (in terms of sales volume dollars and the number of systems in use) equipment alternative for small parts order picking. Bin shelves are inexpensive ($100 to $150 per unit), easily reconfigured, and require very little if any maintenance. Unfortunately, the lowest initial cost alternative may not be the most cost-effective alternative, or the alternative that meets the prioritized needs of a warehouse. With bins shelving systems, savings in initial cost and maintenance may be offset by inflated space and labor requirements. Space is frequently underutilized in bin shelving systems, because the full inside dimensions of a shelving unit are rarely usable. Also, because people may be walking and extracting the items, the height of bin shelving units may be limited by the reaching height of a human being. As a result, the available building cube may also be underutilized.  The consequences of low space utilization are twofold. First, low space utilization means that a large amount of floor space is required to store the products. The more expensive it is to own and operate the space, the more expensive low space utilization becomes. Second, the greater the floor space, the greater the area that must be traveled by the order pickers, and thus the greater the labor requirement and costs. Two additional drawbacks of bin shelving are supervisory problems and item security/protection problems. Supervisory problems arise because it is difficult to supervise people through a maze bin shelving units. Security and item protection problems arise because bin shelving is open; that is, all the items are exposed to and accessible from the picking aisles and by any operator and/ or visitor. Overview of Small Item Storage

Saturday, December 29, 2007 @ 1:47 AM

Tote Pans and Bins In tote picking systems, conveyors are used to transport tote pans through successive picking zones to enable order completion. The tote pans are used to establish order integrity, for merchandise accumulation and containment, and/or for shipping. Order picker may walk one or more totes through a single picking zone, partially completing several orders at a time, or an order picker may walk one or more totes through all picking zones, thus completing one or more orders on each pass through the picking zones. Tote picking rates range from 150 to 300 lines per person-hour. The improvement over cart picking must be sufficient to justify the additional investment in conveying and sorting systems. Modular Storage Drawers/ Cabinets Modular storage drawers/ cabinets are called modular because each storage cabinet houses modular storage drawers that are subdivided into modular storage compartments. Drawer height range from 3 inches to 24 inches, each drawer may hold up to 400 pounds worth of material. Storage  cabinets can be thought of as shelving units that house storage drawers. cabinets can be thought of as shelving units that house storage drawers.The primary advantage of storage drawers/ cabinets over bin shelving is the large number of items that can be stored and presented to the order picker in a small area. A single drawer can hold from 1 to 100 items( depending on the size, shape, and Inventory levels of the items), and a typical storage cabinet can store the equivalent of two to four shelving units worth of material. The excellent storage density accrues from the ability to create item housing configurations within a drawer/ cabinet that very closely matches the cubic storage requirements of each SKU. Also because the drawers are pulled out into the aisle for picking, space does not have to be provided above each SKU to provide room for the order picker’s hand and forearm. This reach space must be provided in bin shelving storage; otherwise, items deep in the unit cannot be accessed. By housing more material in less floor space, the overall space requirement for storage drawers is substantially less than that required for bin shelving. Additional benefits achieved by the use of storage drawers include improved picking accuracy and protection for the items from the environment. Picking accuracy is improved over that in shelving units because the order picker’s sight lines to the items are improved, and the quantity of light falling on the items to be extracted is increased. With bin shelving, the physical extraction of items may occur anywhere from floor level to seven feet off the ground, with the order picker having to reach into the shelving unit itself to achieve the pick. With storage drawers, the drawer is pulled out into the picking aisle for item extraction. The order picker looks down onto the contents of the drawer, which are illuminated by the light source for the picking aisle. Excellent Item security and protection are achieved because the drawers can be closed and locked when not in used. Storage Cabinets equipped with drawers range in price from $1000 to $1500 per unit. Price is primary a function of the number of drawers and the amount of sheet metal in the cabinet. Because the cost per cubic foot of storage is high, storage drawers are only justifiable for items with very little on-hand cubic inventory ( typically less than 0.5 cubic feet) and for operating scenarios in which the cost of space and the need for item security and protection are very high. Mechanised Systems  Carousel Horizontal and vertical carousels are a rotating set of shelves bringing the product to the operator, eliminating walk and search time, which accou8nts for as much as two-thirds of an employee’s time. The vertical carousel, where the inventory moves vertically as with a ferries wheel, is stand-alone unit providing high storage with a very small footprint. On the other hand, horizontal carousels are operated from the nose end and can be clustered, side by side, greatly increasing storage volume while providing a compact working station and allowing dramatic cost efficiencies in certain applications such as split-case order picking. Either horizo0ntal or vertical carousels can be utilized efficiently in a warehouse or distribution center operation. The implementation of a WMS allows for real-time communication with the carousel system to perform the following picking or put-away replenishment activities. Carousel Benefits  In addition to high picking rates and sequenced and batch picking, carousels provide fast replenishment and hot pick capabilities. These machines have an inherent simplicity, reliability, durability, and low routine maintenance. Carousel operators can be easily supervised and fatigue can be sharply reduced because operator travel time is reduced and pick rate per hour is more consistent than that with manual pick systems. Put-away operations and cycle counts can be interspersed with order picking for variety. Today’s carousel designs allow the reengineering of the warehouse process to maximize automation, giving convenience and time savings to downstream activities. Carousels integrate easily with warehouse management systems, increasing the efficiency and accuracy of order picking and inventory management.  Louvre Panel Systems Louvre Panel Systems are mainly used in stores, and also mounted on to trolleys for movement, example between storage and assembly operations. They can be used to hold tote pans, and also other attachments for more awkwardly shaped items such as vee belts, tool holders, etc, using spigots. Video on Small Items Storage

Friday, December 28, 2007 @ 8:41 AM

Overview of Odd Size Storage

@ 6:23 AM

Long Loads Cantilever Rack Certain products require a specialized storage medium. Cantilever racks have arms that allow the storage of long awkward products such as tubular steel, pipes, and lumber. Furniture and boat companies are good examples where the cantilever rack is widely used. This type of storage medium presents unique challenges to a  WMS. Locations defined by the smallest product volume or length to maximize storage capacity. As the product size varies and requires more than one consecutive location for storage, the WMS must have the ability to assign multiple locations to the one product based on the location and product size parameters. Since the directed put-away logic can get complex, an alternative approach is to allow the operator to determine the storage location for the inventory, referred to as assisted put-away. WMS. Locations defined by the smallest product volume or length to maximize storage capacity. As the product size varies and requires more than one consecutive location for storage, the WMS must have the ability to assign multiple locations to the one product based on the location and product size parameters. Since the directed put-away logic can get complex, an alternative approach is to allow the operator to determine the storage location for the inventory, referred to as assisted put-away. Cantilever rack permits a FIFO product rotation, excellent storage density, and excellent product accessibility. The unit-load position has a utilization factor of 85 percent and handles a high volume. Vertical Racks These are also made from vertical frames, connected together by angle-iron horizontal members, but much higher frames are used than for antler racks, and there are no ‘horns’. As the name implies the bars or tubes are stored vertically. These racks have the advantage of making use of the height of the building if long bars or tubes are held, and are thus economical of space. They are inconvenient for really heavy items because of the difficulties of handling and the safety factor, and they are also unsuitable for very light bars or tubes which may become distorted under their own weight. Vertical racks are often fitted with trays on the floor to collect surplus oil draining off the material stored. Pigeon-hole Rack Large quantities of metal plate are best dealt with by simple floor storage and the same way may apply to sheet, although sheet is often kept on pallets if the size is suitable. Sometimes, however, where stocks are not extensive, it may be desirable to have specially designed racks for these materials. Light plate or sheet can be stored horizontally or vertically in a rectangular angle-iron framework, but this arrangement allows manual handling only. Heavier items can be accommodated vertically in a rack made of two steel joists or channels along the floor with uprights of ‘A’ frames at intervals to act as spacers. One incidental advantage of this method is that, if steel plate is kept outside, vertical storage allows the rain to drain off quickly and minimizes corrosion. Where mechanical handling is necessary for heavy plate, the best method is to use a crane with a special attachment known as a plate clamp, which can be fixed on the edge of the plate to allow it to be lifted. Comparison

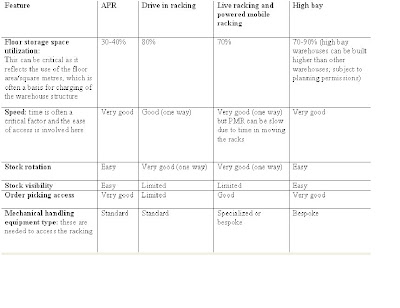

Wednesday, December 26, 2007 @ 11:59 AM

Article on Storage Systems and Material Handing

Tuesday, December 25, 2007 @ 7:17 AM

DC VelocityJune 2006 basic training getting a handle on material handling By Art Van Bodegraven and Kenneth B. Ackerman Warehousing is nothing more than the effective management of time and space. It would stand to reason, then, that the material handling tools used in facilities would be designed to conserve both time and space. But it's never that simple. As we have often observed, warehousing is nothing more than the effective management of time and space. It would stand to reason, then, that the material handling tools used in facilities would be designed to conserve both time and space. But it's never that simple. Inevitably, trade-offs must be made. When space is at a premium, enormous creativity has been applied to finding ways to use the least amount of space possible. When time is the principal driver, it works the other way around. When both labor and real estate costs are high, the time/space economic calculation tends to fly out the window, as highly complex technology solutions are introduced into extraordinarily compact footprints. Choices, choices Within the four walls of distribution centers (and in the yards), material handling equipment is broadly divided into three varieties: static equipment, mobile equipment, and tools to pick orders. Static equipment consists primarily of items without wheels, usually storage equipment in the form of metal rack. While some varieties are movable, none are really mobile. Let's start with racks for pallets, which come in eight basic types. "Single deep" is the most commonly used pallet rack, but it is the design that takes up the most space. "Double deep" requires a lift truck with an extending device that allows pallets to be placed two deep, and it is efficient in any warehouse that normally has at least two pallets of every item. "Self-stacking pallet rack" is a venerable technology that allows a very flexible layout and high-bay storage for products such as tires that have no packaging and no stacking strength. It is also used for some applications in the rug industry. "Drive-in rack" and "drive-through rack" are essentially the same thing, except that the former allows entry from just one side of the installation, and the latter allows entry from either side. "Gravity flow rack" uses skate conveyor to allow product to move downhill from the top of the storage lane to the aisle. "Pushback pallet rack" allows the lift truck operator to store several pallets in a protected row by pushing the older stock uphill. "Mobile rack" is a rack installation on wheels that allows the elimination of unneeded aisles. It can be effective in cases of very limited demand for a large number of SKUs, but is both costly and inefficient for high-volume distribution. Some storage systems are designed to hold units rather than pallets. These include shelving and cantilever rack. The shelving may be something quite similar to that found in any library. Cantilever rack resembles a metal Christmas tree, and its arms are designed to hold long products such as pipe, lumber, vinyl or aluminum siding as well as other items too awkwardly shaped to be transported on pallets. The oldest and perhaps most critical piece of static equipment is the pallet itself. Virtually invented to accommodate the forklift truck, pallets had no standard for size or construction method until the 1960s, when General Foods demanded that pallets be built with some degree of uniformity so they could be exchanged without penalty. The passage of time has degraded the quality specifications that were built into the General Foods pallet, but its size of 48 by 40 inches has become a widely accepted standard—even in the European Union with a metric equivalent. Nevertheless, some companies and industries, notably telecommunications, continue to go their own way in defining the "standard" pallet. On the move The next major category is mobile equipment. Manually powered handling vehicles are the oldest devices and they are still widely used. They include two-wheeled hand trucks, four-wheeled platform trucks and hydraulic pallet movers. The "Model T" of material handling is the counterbalanced forklift truck. It is the most widely used motorized material handling vehicle. As the technology evolved, forks were augmented with a variety of other attachments, such as clamp devices to hold cartons or paper rolls, push-pull attachments designed to handle fiberboard pallets that are called slipsheets, and multi-pallet forks designed to haul several unit loads at a time. While the earliest lift trucks were powered by internal-combustion gasoline engines, later models were developed to handle other fuel sources, including propane, diesel and CNG (compressed natural gas). Battery-powered electric vehicles became a popular replacement for internal combustion, and hybrid gas/electric power was developed for lift trucks long before it was seen in automobiles. Research is well under way toward developing fuel cells to power lift trucks. For use in operations where space is at a premium, lift truck manufacturers have produced vehicles that are designed to run in narrow or very narrow aisles. The most extreme is the turret truck that has a device that turns the fork carriage without turning the remainder of the vehicle. These trucks can operate in an aisle just a few inches wider than the truck itself. Tools for the picking In most warehouses, selection of orders is the single most expensive part of the warehousing process. Conveyors and sorters are the most expensive, but also perhaps the most effective, means of reducing the labor involved in order picking. Most conveying systems are a combination of mobile and static equipment. The frame is static, but there are rollers or wheels within the frame. Gravity flow rack has two varieties, one that moves single cases and flow rack that moves full pallets. A central question in order picking is whether to move the order picker to the part, or move the part to the picker. Carousels and automated storage and retrieval systems (AS/RS) are designed to bring the product to the picker (or to the point of use in the case of some manufacturing applications). Carousels can be effective when there are sufficient numbers of items—of appropriate size and weight—with relatively modest demand profiles. They may be less than optimal if the application requires fewer than two or three units. AS/RS enjoyed a tax-incentive-fueled vogue in the United States some years ago, but fell out of favor as the just-in-time wave swept over industry and the tax incentives were eliminated. They have remained popular and useful in places where labor and real estate costs are high, notably Japan, Singapore, Hong Kong, and Europe, and still may be a good choice in some applications in North America. Comprehensive systems for conveying and sorting are a must for large distribution centers supporting high-volume order fulfillment. They can involve literally miles of motorized conveyor, induction stations, recirculation lanes and readers or scanners. They also require sophisticated control systems for reliable operation. Powerful and impressive as they can be, their planning and implementation demands that they not be made too sophisticated and rigid. The pace of change in the supply chain world requires operational flexibility. Sortation, alone, introduces a number of solution alternatives into the material handling equation. Principal varieties include pop-up sorters, push diverters, sliding shoe sorters, tilt-tray sorters, bomb-bay sorters and turnstile diverters. Other order selection tools are more software- than hardware-driven. Options include pick-to-light, a combination of case gravity flow or motorized rack, and signal lights that allow the order selector to complete the job by simply following a trail of illuminated signals and taking the signal-indicated number of pieces. Voice recognition is one of the most recent innovations in material handling technology. It allows warehouse workers to achieve better accuracy while at the same time increasing speed. The worker wears a headset and receives instructions on the next task. Because the technology is handsfree and eyes-free, the worker is able to move from one task to the next without paper lists or scanning guns. Radio-frequency identification is a technology that has been around for a while. But driven by demands from retailers and the Department of Defense, it has generated more frenzied publicity than just about any other technology over the last couple of years. The key ingredient is a chip embedded in the product, in its packaging, or in its documentation. Leaders in almost every industry segment are experimenting with, or even developing, technology and process alternatives, seeking practical and cost effective applications. So, how do you choose? We suggest asking the following eight questions to determine the best approach to improving order picking and to implementing mechanization and control systems: - How many stock-keeping units are maintained and what is the distribution of demand among them? - How many lines per order? - What is the average order size and weight? - Are there multiple order profiles that need design recognition? - Is batch picking practical? What are the pick wave options? - How frequently are orders picked within a shift, within a day? - How critical is order cycle time? What are the mission-critical time cut-offs? - How are today's customer, product and order profiles—and service requirements—likely to change over the next five years? The evolution from hand-powered material handling devices to the most sophisticated conveying and sorting has almost always been based on the need to reduce the human effort required for order selection and shipping, as well as in receiving and stocking goods. The evaluation of alternatives and the acquisition of solutions demand a thorough analysis—and a rational business case. It's not a matter of what has the most bells and whistles. Depending on the application, the right solution may also be the simplest solution and the one with the lowest cost. http://www.dcvelocity.com/print/?article_id=155">www.dcvelocity.com/print/?article_id=155 Article on the way you set things up can pay off greatly

Monday, December 24, 2007 @ 8:10 AM

This article appeared in Parcel Shipping and Distribution in December, 2005.Rack up the Value The way you set things up can pay off greatly By Jason Deiter As an inside sales representative for a major material handling company, half of the phone calls I receive start the same way: "I'm looking for racking." It's a promising start, but it's usually followed by, "I'm not sure how much I need," "I don't know what kind I need" or "I am new to this." I could be hundreds or even thousands of miles away from these potential customers and their problems, but with the help of faxes, email, the Internet and digital cameras, we are usually able to share enough information to develop a proposed layout and a request for quotation. People new to the warehouse or purchasing start out knowing that they have product sitting on the floor taking up space needing to utilize their vertical space better. After all, they are not just paying for square footage; they are heating, cooling and maintaining a three-dimensional space. Even more importantly, that vertical space is a wasted asset that could be used to store needed inventory and can free up floor space for more productive uses. What else do you need to know? In just a few minutes, you can gather all the information you need before calling your sales representative. This includes: The length, width and height of a single pallet that has product on it. The weight of the pallet with product. The clear height on the warehouse - that is, the actual usable inside height of the warehouse at its lowest and highest points. Your forklift's specifications, especially dimensions and lifting capacity. The length of the rows of racking you wish to create. The number of pallets you wish to store. Decide whether you want used, renewed or new material. Drive in for More Space Let's start with the last one first. Face it, racking is racking. It rarely becomes obsolete because of new technology. If your needs can be met by quality refurbished racking, you will save money. However, in order to be certain that your needs will be met, make certain you trust your supplier and the refurbishing process they employ. Most material handling vendors that deal in used and renewed equipment have finely tuned their methods of pricing in order to give you a quote based on the information listed above. Let's use drive-in racking as an example. Drive-In racking is a type of "last in, first out" (LIFO) racking meaning product is loaded as far back in the rack as it will go. When unloading, the nearest available pallet is selected from the same side, as opposed to a FIFO (first in, first out) system where you usually load the product from the rear. In FIFO applications, product either flows to the forward of first position on a conveyor or it will be driven through the system. Drive-in systems are widely used throughout the warehouse industry in places that have large volumes of pallets to store and seek an affordable, dense pattern. If you have a warehouse with clear floor space, high ceilings and hundreds of pallets to store on a tight budget, the choice is simple. Instead of creating a maze of rows and aisles, as you would with standard selective pallet racking, you create one large grid with access on a single side to drive in. Keep in mind that the space savings are not the only benefit you will realize, although an estimated 80-85% space utilization can be achieved. Another factor in calculating your return on investment (ROI) is the potential savings in labor, equipment, product damage and operating costs. Even so, gaining 50% more capacity to store your loads in an existing space can be very attractive when you consider the cost of additional warehouse space. Instead of figuring out which direction you are going to grow and how big an addition you will need for your building, you will instead think of the things that you can do with the space left over after consolidating. Advantages of a Clean Floor After doing away with selective pallet racking and consolidating into one easy to access area, you will soon realize the rest. You will instantly notice that you are no longer driving down aisles to find product, turning corners and dodging the pallets that have been left on the floor, obstructing your path. Another noticeable difference is that there are fewer upright frames that can be damaged. Once you turn into the drive-in system past the front uprights, your forklift is between a set of drive-in rails on which the pallets rest (except the bottom one). The product is further protected if the system is designed to allow only pallet loads that are confined to the size of the pallet. Systems designed for product overhang are still able to provide a certain level of protection. Usually, the forklift that operated within the structure will be the same unit that loads and unloads freight from a truck. The distance traveled by the forklift decreases per pallet retrieved or stored, reducing wear and tear on the unit. The ability to access the pallets faster and safer means that you can also increase your rate of picking per man hour, again increasing your ROI. Another way to save your company money by using drive-in racking is to double-stack your pallet loads on the bottom level. This will increase the maneuverability of the forklifts and will systematically reduce loading and retrieval time by carrying two pallets at once. This can only be done where identical SKU's are stored and cubed loads of the same items are forecasted for shipment. Pallet loads must be stable and free standing while you double-stack them, without causing damage to the product. The total combined weight of the double stack must not be more than what the forklift is able to handle. These are just a few of the things you can think about before calling your sales representative. Other issues will come up before you make your purchasing decision, but a little planning can save a lot of time. Jason Deiter is a sales representative for SJF Material Handling, Inc. of Winsted, Minnesota, a nationwide supplier of material handling equipment and services for 27 years. http://www.sjf.com/news-stories.html#news32 Article- Cantilever Rack reduces waste, simplifies handling

Sunday, December 23, 2007 @ 10:26 PM

Cantilever rack reduces waste, simplifies handlingBuffalo Veneer and Plywood, located in Buffalo, Minnesota, is a supplier of specialty plywood using common North American tree species. By Staff -- Modern Materials Handling, 10/2/2005 Buffalo Veneer and Plywood, located in Buffalo, Minnesota, is a supplier of specialty plywood using common North American tree species. While others in their industry have focused on large lot sales and a few woods, Buffalo Veneer remains true to its roots. "We supply oak and birch plywood to Menards and Home Depot, but we also deal with fine cabinet makers all over the country," says Paul Erickson, company president. "We still do custom four or five sheet orders. Our reputation was built on quality and our ability to work with a variety of materials." This kind of craftsmanship can be expensive, but it also means that Buffalo Veneer can get top dollar for the two to three truckloads of product it ships each day. The downside to this high-end market position is the cost of waste, which becomes a significantly more expensive problem as the cost of each unit goes up. The company was experiencing some costly problems in their finished wood storage and staging area. Sheets were simply stacked on top of each other leading to hazardous lifting and product damage. The answer to these problems was to install modular cantilever rack storage. The modular nature of the system meant that it could easily fit the available space, including the full building height that so often goes to waste in many storage facilities. Heavy duty enough to handle the heaviest loads, the modular system can be reconfigured or added onto as needed. Wood sheets now stored individually or in small bundles to reduce abrasion and scratch damage. The product is off the floor and out of traffic lanes, eliminating accidental damage from heavy equipment. Pallets are also eliminated, along with the strap damage that goes with them. |